Feed Technology – Fully Digitalised

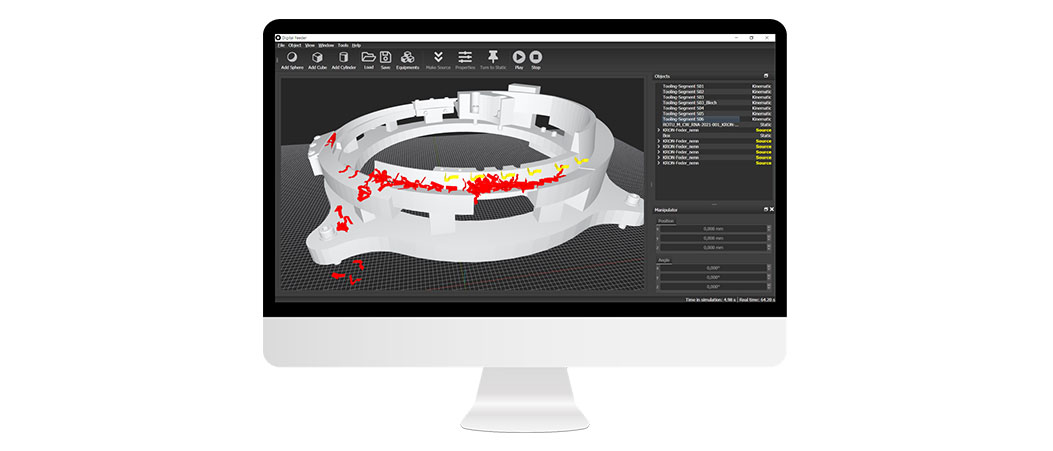

“Digital Feeder” Simulation Programme. Photo: RNA

Feed systems are indispensable for automation in assembly and production. A diverse range of components, parts, assemblies and end-products have to be fed and discharged in individualised configurations for production processes – a key step in manufacturing operations. As a result, feed technology has always been one of the core topics at Motek/Bondexpo. Rhein-Nadel Automation GmbH (RNA) from Aachen, Germany, supplies fully digitalised feed systems equipped with artificial intelligence and multiphysics simulation, and offers a preview of the company’s trade fair highlight for autumn 2024.

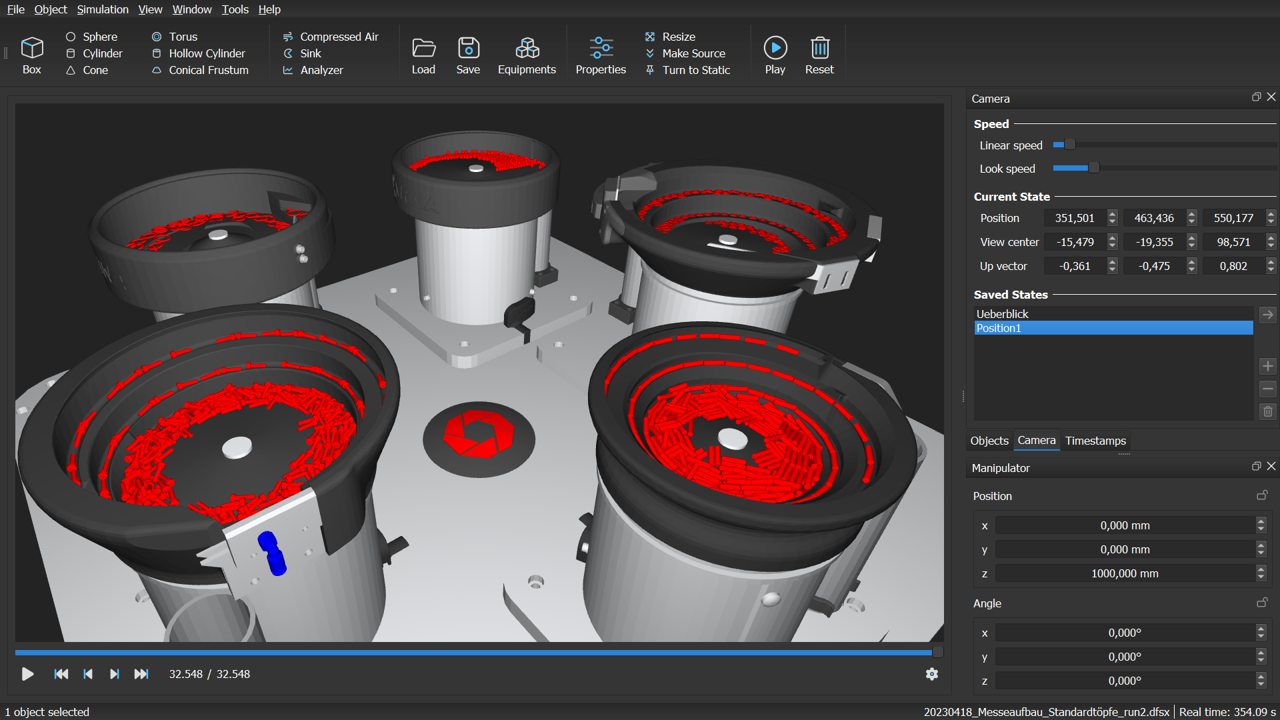

RNA is firmly focused on the topic of digitalisation, which is why their booth at this year’s Motek will feature a consistently digital layout. In order to be able to demonstrate the advantages to visitors in an ideal manner, the booth will feature various touchscreens, as well as reproducible digital feeding systems. Thanks to simulation programmes including Digital Motion for coordinating actuators and Digital Feeder for simulating parts, customers are able to digitally validate every reproducible feed system (FlexType series) during the design phase by simulating the sorting process, before production of parts and components begins. This makes it possible to ensure that the sorting or feed solution functions correctly before the system is set up. And this saves time and money. Furthermore, the use of production resources is minimised, duplication of work is avoided and the system can be qualified more efficiently. In addition to SolutionFinder, an internal search engine that helps to identify the right solution based on an AI algorithm during the project planning phase, an app has also been created that makes it possible to develop concepts in detail. In the long term, this will allow RNA to create simple sorting solutions and system concepts automatically by means of AI, so that the technical specialists can concentrate their full attention on the complex applications. The solution speeds up the process, increases application safety and significantly reduces the risk on both sides.

Digitalised feed systems from RNA provide users with suitable, reliable solutions for their workpieces.

Photo: RNA